|

+Pro/SHEETMETAL Training

Course Duration:

16 Hours

Tuition: $1200 US

Overview: This comprehensive suite of

sheet metal design tools in Pro/ENGINEER-Foundation helps users create

features such as walls, bends, punches, notches, forms, and relief features.

Using a variety of Y and K factor bend allowance calculations, designers

can create flat patterns of the designs. The result is parametric, fully

associative solid models of sheet metal parts and assemblies. Students

have the option to customize this course to fit project requirements.

Prerequisites: 400 hours minimum experience

with Pro/ENGINEER and a willingness to learn.

Topics:

- Basics of Pro/SHEETMETAL

- Bends

- Extruded walls

- Swept walls

- Relief's, no relief, stretch, rip, rect, obrnd

- Rips

- Hems

- Bend, unbend, bend back

- Form features

Exercise:

- Layout and develop Pivot Bracket. 3/32" Aluminum bracket then

add a Flat State instance.

- Build another bracket with bends and extruded walls with a variety

of challenges.

- Model dust cover for back of computer using stamp (Form features)

- Create multiple parts that lock together such as a sheet metal computer

power supply.

- convert to sheet metal an enclosure from a solid geometry and discuss

a wide variety of convert tools.

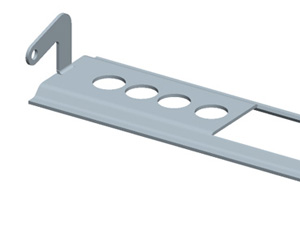

This bracket has several challenges for beginning sheet metal users.

Discussion:

- Discuss differences between Pro/ENGINEER thin features and Pro/SHEETMETAL

- Discuss designing sheet metal parts

- Flatten out the part to visualize design and manufacturing needs.

- Make Drawings of the sheet metal part, incorporating Dimensions, Bend

Order tables, Flat Patterns and fully designed parts.

- Discuss order of feature creation

- Discuss why rips are important with respect to stretching

- Discuss warn out tooling and how to compensate using Bend Tables

- Discuss 2001 and Wildfire or Wildfire 2.0 iconography.

- Discuss modeling techniques such as starting out with non sheet metal

models and converting to sheet metal later to take advantage of shell

features.

Project: Several Brackets, Deep drawn

form and combination. Curriculum can be combined with Pro/SURFACE tools

for automobile sheet metal functions or for smaller battery contacts to

mating components such as sheet metal boxes to house a computer power

supply.

Pro/SHEETMETAL, like Pro/ENGINEER, allows flexibility in design. Changes

are made and updated parametrically throughout the entire design process.

This video pivot offers several road blocks for designers learning sheet

metal and for the the experienced alike.

This power supply uses a form feature to push out the fan area.

A good third project for this two day sheet metal workshop.

|